Metallvärmebehandling och de välkända "fyra bränderna"

Metal heat treatment is a process in which a metal workpiece is heated in a chosen medium to an appropriate temperature, held at that temperature for a certain time, and then cooled in different media at different rates, in order to control its properties by changing the microstructure at the surface or in the bulk.

The heat‑treatment process generally comprises three stages: heating, soaking (holding), and cooling.

The overall heat treatments commonly referred to as the dddhhhfour firesdddhhh are the four most frequently used methods: annealing, normalizing, quenching, and tempering.

Annealing Annealing is a heat treatment in which steel is heated to a specified temperature, held for a period, and then cooled slowly with the furnace. The resulting microstructure is typically pearlite and ferrite. The main purposes of annealing are to eliminate structural defects, homogenize composition, refine grain size, and improve mechanical properties. Annealing also reduces hardness, increases ductility and toughness, and improves machinability.

Normalizing Normalizing involves heating steel above a certain temperature so that it fully transforms to austenite, then cooling it in air. The resulting structure is commonly sorbite (a fine pearlitic structure). Compared with annealing, normalizing cools at a faster rate, producing a finer microstructure and somewhat better mechanical properties. Normalizing is also less time‑consuming and does not occupy the furnace for as long, so it has higher productivity.

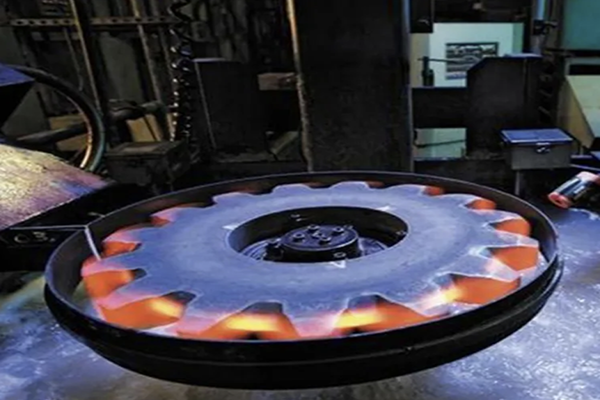

Quenching Quenching is a heat treatment in which steel is heated above a specified temperature, held, and then rapidly cooled by immersion into a quenching medium so that its temperature drops sharply at a rate exceeding the critical cooling rate. This produces a mainly nonequilibrium structure such as martensite or lower bainite. Quenching increases strength and hardness but reduces ductility. Common quenching media include water, oil, alkaline solutions, and salt solutions.

Tempering Tempering is reheating previously quenched steel to a certain temperature and then cooling it by a specified method. Tempering can be classified by temperature into low‑, medium‑, and high‑temperature tempering:

Low‑temperature tempering (150–250°C): aims to retain high hardness and wear resistance from quenching while reducing internal stresses and brittleness to prevent cracking or premature failure in service.

Medium‑temperature tempering (350–500°C): aims to achieve high yield strength, a good elastic limit, and improved toughness.

High‑temperature tempering (500–650°C): quenching followed by high‑temperature tempering is commonly called quench‑and‑temper; its goal is a balanced set of mechanical properties — good strength, hardness, ductility, and toughness.

Most of our company’s products require one or more of the above heat treatments. Different materials call for different heat‑treatment schedules. The four principal drill tool components — the drilling bit , drill rod, coupling sleeve, and shank adapter — all require heat treatment, so heat‑treatment practices are especially important in our machining industry and for rock‑drilling tools. Do not underestimate these four “fires”: if any one is mishandled, previous work can be undone. Study, research, and accumulate experience.